How is Wood Veneer Made

Wood veneer is a thin layer of real wood that is glued to a substrate. It is available in sheets and can be applied to furniture, cabinets, walls, and floors. Veneer is made by slicing a log into thin strips or peeling it with a rotary cutter.

The strips are then glued together to form a sheet.

Wood veneer is a thin layer of wood that is used as a decorative surface. It is often used on furniture and cabinets, as well as on floors and walls. Veneer is made by slicing a log into thin sheets.

The thickness of the sheets can vary, but they are typically between 1/16 and 1/8 inch thick.

The process of making wood veneer begins with choosing the right tree. The tree must be large enough to provide the necessary amount of veneer, and it must be free of knots or other blemishes that would mar the final product.

Once the tree has been chosen, it is cut down and brought to a sawmill.

At the sawmill, the log is placed on a large cutting machine called a lathe. The lathe spins the log while a blade slices it into thin sheets.

The thickness of the sheets depends on how much pressure is applied to the blade; more pressure results in thinner sheets.

After the log has been cut into veneer, it needs to be dried. This can be done either by air-drying or by kiln-drying.

Kiln-drying is faster but it can damage delicate woods such as mahogany or cherry. Air-drying takes longer but it doesn’t have this risk.

Once the veneer sheets are dry, they are ready to be used in any number of applications.

Disadvantages of Veneer Wood

Veneer wood is a type of engineered wood that is made by bonding together thin layers of wood. It is often used in furniture and cabinetry because it is less expensive than solid wood and can be made to look like almost any type of wood. However, there are some disadvantages to using veneer wood.

One disadvantage of veneer wood is that it is not as strong as solid wood. Because it is made up of thin layers of wood, it can be more prone to warping, cracking, and chipping than solid wood. Additionally, veneerwood can be sensitive to changes in humidity and temperature, so it may not be the best choice for areas that experience extreme weather conditions.

Another downside to veneered wood is that it is difficult to repair if it becomes damaged. Once a piece of veneered wood has been damaged, the entire piece will likely need to be replaced since it’s very difficult to sand down or refinish just the damaged area without affecting the rest of the piece.

If you’re considering using veneer wood for your next project, weigh the pros and cons carefully before making your decision.

While veneered woods can offer a beautiful finish at a lower cost, keep in mind that they may not withstand wear and tear as well as solid woods and they can be tricky to repair if they become damaged.

Wood Veneer Sheets

Wood veneer sheets are a type of wood paneling that is often used for decorative purposes. They are made by slicing thin layers of wood from a larger piece of lumber, and then pressing them together to form a sheet. Wood veneer sheets can be found in a variety of colors and grain patterns, making them a versatile material for use in home decorating.

Wood veneer sheets have many advantages over solid wood panels. They are lighter in weight, which makes them easier to work with and install. They are also more stable than solid wood, meaning they will not warp or cup over time.

And because they are made from thin layers of wood, they can be less expensive than solid wood panels.

If you are considering using wood veneer sheets in your next home decorating project, here are a few tips to keep in mind:

– Choose the right thickness for your project.

Wood veneer sheets range in thickness from 1/16 inch to 1/4 inch. If you need a lightweight panel for use on walls or ceilings, choose a thinner sheet. For heavier duty projects like furniture or cabinetry, choose a thicker sheet.

– Consider the color and grain pattern of the wood veneer when making your selection. There is a wide range of colors and grain patterns available, so take some time to browse before making your final choice. Keep in mind that the color and grain pattern of the sheet may vary slightly from the sample you see at the store due to natural variations in the wood itself.

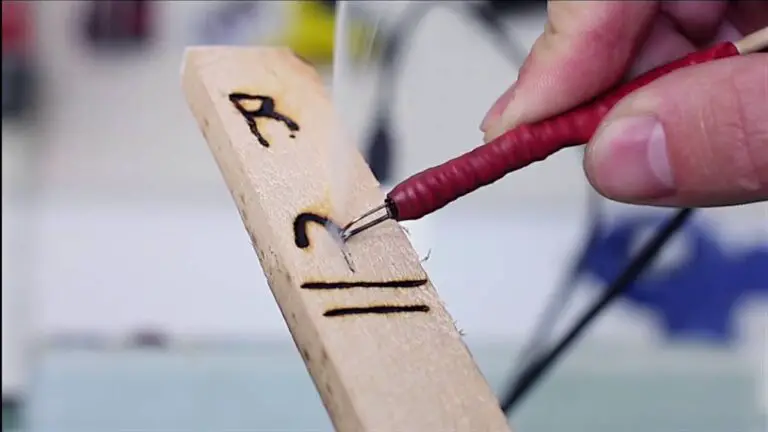

How to Make Wood Veneer by Hand

Wood veneer is a thin layer of wood that is typically used as a decorative covering for furniture and other wood products. Veneer is made by slicing a log into thin sheets, and can be either hand-made or machine-made.

Machine-made veneer is generally thinner and more uniform in thickness than hand-made veneer, but both types can be used for many different applications.

Hand-made veneer often has a more rustic appearance, with each sheet being slightly different in thickness and shape. This can give your project a unique look, and also allows you to use smaller pieces of wood since the sheets are not all exactly the same size.

To make your own hand-made wood veneer, start by choosing a straight-grained hardwood log that is at least 18 inches in diameter.

Cut the log into manageable sections using a saw, then slice each section into thin sheets using a sharp knife or an electric slicer. A mandoline slicer will give you the thinnest possible slices, but takes some practice to use without injuring yourself! Once your slices are cut, sand them smooth on both sides using progressively finer grits of sandpaper until they are silky smooth.

Now you’re ready to use your hand-made wood veneer for whatever project you have in mind! You can glue it onto another piece of wood using an adhesive designed for bonding wood (such as Titebond II), or apply it directly to surfaces like walls or cabinets with double-sided tape. Experiment with different woods and slicing techniques to create unique looks for your home projects!

Veneer Manufacturing Process

The veneer manufacturing process involves cutting thin sheets of wood from a larger piece of lumber. Veneers are typically used in cabinetry, furniture making, and other woodworking applications where a smooth, consistent surface is desired.

There are two main methods for cutting veneers: rotary cutting and slicing.

Rotary cutting is done with a large cylindrical blade that spins around the piece of lumber being cut. This method is typically used for thicker veneers (5mm or more). Slicing, on the other hand, uses a sharp blade to slice through the lumber like a knife; this method is better suited for thinner veneers (3mm or less).

Once the veneers have been cut, they must be trimmed to size and then glued onto a substrate (usually plywood or MDF). The trimming process involves using a router or saw to remove any rough edges. After trimming, the veneer sheet should be sanded smooth before being glued down.

To glue the veneer onto the substrate, you will need to use an adhesive designed specifically for bonding wood. Once the adhesive has been applied to both surfaces, simply press them together and allow the glue to dry completely before proceeding with your project.

Wood Veneer Vs Laminate

When it comes to choosing between wood veneer and laminate for your next home improvement project, there are a few things you need to keep in mind. Both materials have their own unique set of pros and cons, so it’s important to weigh all of your options before making a final decision.

To help you out, we’ve put together a quick guide comparing wood veneer vs laminate.

Read on to learn more about each material and see which one is right for your needs!

Wood Veneer: Pros and Cons

Pros:

-Gives off a natural look that can add warmth to any space.

-Can be sanded down and refinished if necessary.

-Relatively easy to install yourself.

Cons:

-More expensive than laminate.

-Easier to damage than laminate (scratches, stains, etc.).

Laminate: Pros and Cons

Pros:

-Much less expensive than wood veneer.

-Resists scratches, stains, and other forms of damage much better than wood veneers.

-Available in a wide variety of colors and finishes.

Cons:

-Gives off a more “fake” or “plastic” look than wood veneer.

-Cannot be sanded down or refinished like wood veneers can be.

Credit: www.woodworkingnetwork.com

What are Disadvantages of Veneer Wood?

Veneer wood is a type of plywood made with thin veneers of real wood glued together. It is an inexpensive alternative to solid wood and can be used for a variety of purposes, including furniture, cabinets, and flooring. While veneer wood has many advantages, there are also some disadvantages to consider before using it in your next project.

One disadvantage of veneer wood is that it is not as strong as solid wood. This means that it is more likely to dent or scratch than solid wood furniture. Additionally, veneer wood can delaminate over time if it is not cared for properly.

If the glue holding the layers of veneer together begins to fail, the layers can peel apart, leaving your furniture looking damaged and ruined.

Another downside to using veneer wood is that it does not age well. Solid wood furniture can last for generations with proper care, but veneer furniture will start to show its age after just a few years.

The thin layers of real wood can also warp or crack over time due to changes in humidity or temperature.

If you are considering using veneer wood for your next project, weigh the pros and cons carefully before making your decision. Veneerwood has its advantages, but it may not be the best choice for every situation.

What is Veneer And How is It Manufactured?

Veneer is a thin layer of material that is used to cover another object. It can be made from a variety of materials, including wood, metal, and plastic. Veneer is typically glued or bonded to the object it is covering.

There are two main types of veneer: engineered and natural. Engineered veneer is made by slicing a sheet of material into thin layers. Natural veneer is made by peeling a log into thin layers.

Both types of veneer can be used for a variety of applications, including furniture, floors, and walls. Veneer can be stained or painted to match the surrounding décor. It is also available in a variety of colors and textures.

What is Underneath Wood Veneers?

Wood veneers are thin sheets of wood that are applied to the surface of a piece of furniture. The veneer is glued to the surface and then sanded down to create a smooth, finished look. Underneath the wood veneer is usually a layer of plywood or particle board.

This provides stability and support for the veneer.

Is Wood Veneer Fake Wood?

Wood veneer is a thin piece of wood that is used to cover a surface. It is often used to give the appearance of real wood, but it is not solid wood. Veneer can be made from different types of wood, including cherry, maple, and oak.

How wood veneer is made…

Conclusion

Wood veneer is a thin layer of wood that is typically glued onto a substrate for stability and decorative purposes. There are many different ways to make wood veneer, but the most common method involves cutting the desired shape out of a log with a rotary blade. The log is then peeled or sliced into thin sheets which can be applied to furniture, walls, floors, and more.