What to Put between Concrete And Wood

When it comes to your home, one of the last things you want is for there to be cracks in your foundation. That’s why it’s important to know what to put between concrete and wood when you’re installing or repairing your home’s foundation. In most cases, a layer of tar paper is all that’s needed to create a barrier between the two materials and prevent moisture from seeping through and causing damage.

When it comes to choosing what to put between concrete and wood, there are a few different options. The most common way is to use a product called expansion joint filler. This is a flexible material that helps prevent cracking by allowing the two surfaces to expand and contract with temperature changes.

Another option is to use caulk. This can be either silicone or latex based, and helps fill in any gaps between the concrete and wood. It’s important to choose a type that is specifically designed for outdoor use, as regular caulk can degrade quickly in direct sunlight and moisture.

Finally, you could also use foam insulation board. This provides both a physical barrier between the two surfaces as well as thermal insulation. It’s important to make sure that the board is rated for exterior use, as some types of foam board can disintegrate when exposed to the elements.

No matter which option you choose, be sure to follow the manufacturer’s instructions carefully in order to ensure optimal results.

Does Concrete Bond To Wood?

Best Sealant between Concrete And Wood

There are many different sealants available on the market, but which one is best for concrete and wood? We’ve done the research to find the best sealant between concrete and wood.

Concrete is a porous material, which means it can absorb water and other liquids.

This can cause problems if you’re trying to protect your wooden floors or furniture from moisture. A good sealant will create a barrier between the concrete and the wood, preventing moisture from seeping through.

There are two main types of sealants: water-based and solvent-based.

Water-based sealants are less toxic and easier to apply, but they don’t last as long as solvent-based sealants. Solvent-based sealants provide a more durable barrier, but they’re more difficult to apply and have a strong odor.

We recommend using a water-based sealant for most applications.

If you need a more durable barrier, you can use a solvent-based sealant in high-moisture areas such as bathrooms or kitchens.

Vapor Barrier between Concrete And Wood

If you are putting a new floor in your home, you may be wondering if you need to put a vapor barrier between the concrete and the wood. The answer is maybe. It depends on several factors, including the climate you live in and the type of wood flooring you are installing.

In most cases, a vapor barrier is not necessary. Concrete is already fairly impermeable to water vapor. However, if you live in an area with high humidity or if you are using engineered hardwood floors, which are more susceptible to moisture damage than solid hardwood floors, it is a good idea to put a vapor barrier between the concrete and the wood.

There are two main types of vapor barriers: polyethylene sheets and asphalt-coated kraft paper. Polyethylene sheets are less expensive but they can tear easily and they don’t adhere well to concrete, so they may not provide a completely airtight seal. Asphalt-coated kraft paper is more expensive but it’s much stronger and it adheres well to concrete, so it provides a better seal.

Installing a vapor barrier is relatively simple. If you’re using polyethylene sheets, just lay them down on the ground before you start laying your flooring. If you’re using asphalt-coated kraft paper, roll it out on top of the concrete and then staple or tape it down around the edges.

Make sure there are no gaps or holes in the barrier; otherwise, moisture could seep through and damage your floors.

Sill Plate Moisture Barrier

If you’re like most homeowners, you probably don’t give much thought to your sill plate—the board that sits on top of your foundation and forms the bottom of your wall. But if you’re considering adding a moisture barrier to your home, the sill plate is an important element to consider.

A sill plate moisture barrier is a material that helps prevent water from seeping through the cracks and joints in your foundation and into your home.

There are many different types of materials that can be used as a sill plate moisture barrier, but one of the most popular is polyethylene film. This type of material is often used in commercial construction because it’s durable and effective at keeping water out.

When choosing a material for your sill plate moisture barrier, it’s important to select one that will be compatible with the type of foundation you have.

For example, if you have a concrete foundation, you’ll want to choose a material that won’t degrade when it comes into contact with concrete. Polyethylene film is a good option for this type of foundation.

Once you’ve selected the right material for your needs, installing a sill plate moisture barrier is relatively easy.

The first step is to clean the surface of your foundation so that the barrier will adhere properly. Next, apply a layer of sealant or caulking around the perimeter of your foundation. Then simply lay down the sheet of polyethylene film and secure it in place with tape or another adhesive product.

Although installing a sill plate moisture barrier may seem like an extra step in protecting your home from water damage, it can save you thousands of dollars in repairs down the road. So if you’re concerned about water seepage, take the time to install a moisture barrier today—it could be one of the best decisions you ever make for your home!

Sealing Joint between Wood And Concrete

It is important to seal the joint between wood and concrete to prevent moisture from seeping in and causing rot or mold. There are a few different ways to do this, but the most common is to use caulk. You can also use expanding foam, which is great for larger gaps, or weatherstripping.

Whichever method you choose, be sure to clean the surface of the wood and concrete first so that the sealant will adhere properly.

Credit: studioapartmenthub.com

Do I Need a Moisture Barrier between Concrete And Wood?

When it comes to your home, protecting it from water damage is always a priority. That’s why when you’re building or renovating, using a moisture barrier between concrete and wood is an important step to take.

Water can cause serious damage to wood, especially if it’s left untreated.

Wood that’s constantly exposed to moisture is more likely to rot, warp, and develop mold and mildew. A moisture barrier helps prevent all of these problems by creating a water-resistant barrier between the concrete and the wood.

There are two types of moisture barriers: sheet membranes and fluid-applied coatings.

Sheet membranes are made of rubber or plastic and are installed like a giant sheet of tape over the concrete before the wood is installed. Fluid-applied coatings are applied directly to the concrete with a brush or roller and then allowed to dry completely before the wood is installed.

Both types of moisture barriers are effective at protecting against water damage, but they have different advantages and disadvantages.

Sheet membranes are generally less expensive than fluid-applied coatings, but they can be more difficult to install properly. Fluid-applied coatings provide better protection against waterproofing chemicals that may be present in concrete, but they can be more expensive and time-consuming to apply correctly.

No matter which type of moisture barrier you choose, make sure you follow all installation instructions carefully so that your home will be protected against water damage for years to come!

Can You Put Wood Directly on Concrete?

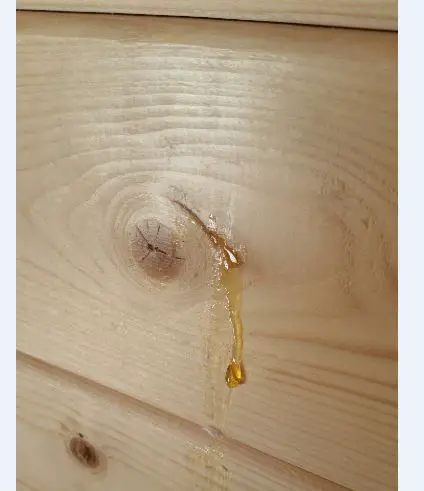

There are a few things to consider when deciding if you should put wood directly on concrete. The first is the moisture content of the concrete. If the concrete is too moist, it can cause the wood to rot.

The second is the type of wood you’re using. Hardwoods are better suited for direct contact with concrete than softwoods. Finally, you’ll need to make sure the concrete is properly sealed before putting anything on top of it.

How Do You Protect Wood in Contact With Concrete?

It is important to protect wood in contact with concrete to prevent rot and decay. There are several ways to do this:

One way is to use a moisture barrier between the wood and concrete.

This can be done by either painting the concrete with a waterproof sealant or by using a sheet of plastic or other material as a barrier.

Another way to protect wood in contact with concrete is to keep it elevated off the ground. This can be done by using spacers or standoffs when attaching the wood to the concrete.

This will allow air to circulate underneath the wood, helping to keep it dry and preventing rot.

Finally, it is also important to make sure that any cracks or gaps in the concrete are filled. This will help prevent water from seeping into these areas and coming into contact with the wood.

Conclusion

When building a deck or outdoor walkway, you need to consider what you will put between concrete and wood. There are many options available, but the best one for your project depends on the climate, the location of the project, and your budget.

One option is to use pressure-treated lumber.

This type of wood is treated with chemicals that make it resistant to rot and insects. It is a good choice for wet climates or locations where the deck will be in direct contact with soil. Pressure-treated lumber is also less expensive than some other options.

Another option is to use composite materials. Composite materials are made from recycled plastic and wood fibers. They are very durable and require little maintenance.

Composite materials are a good choice for dry climates or locations where the deck will not be in direct contact with soil. However, they are more expensive than pressure-treated lumber.

If you are unsure about which material to choose, consult a professional contractor or deck builder.