How to Seal Wood Coasters

If you’re looking for a quick and easy way to add a personal touch to your home décor, wood coasters are a great option. Not only are they relatively inexpensive, but they’re also easy to make yourself with just a few supplies. Plus, if you seal them properly, they’ll be protected from water damage and staining.

Here’s how to do it:

Start by sanding the coaster in all directions until the surface is smooth. Then, wipe away any dust with a damp cloth.

Next, apply a thin layer of wood sealer evenly across the coaster using a brush or roller. Be sure to work in small sections so that the sealer doesn’t dry before you have a chance to spread it around. Once the entire coaster is covered, allow it to dry for at least 24 hours before using it or putting it on display.

- Gather your supplies: wood coasters, a sealer (We recommend Mod Podge Dishwasher Safe Gloss), a foam brush, and scissors (if you are using printed napkins)

- If you are using printed napkins, cut them into squares that will fit nicely on your coasters

- Apply a thin layer of sealer to the top of each coaster with your foam brush

- Adhere your napkin squares to the top of each coaster, smoothing out any wrinkles or bubbles

- Allow the coasters to dry for at least 2 hours before use

- Once dry, apply another layer of sealer over the top of each coaster for extra protection

Credit: gardentherapy.ca

How Do You Seal Homemade Coasters?

If you’re looking to seal your homemade coasters, there are a few different options you can choose from. You can use a clear sealer like polyurethane or Mod Podge, or you can opt for something more durable like resin.

Clear sealers will help protect your coasters from water damage and staining, but they won’t make them completely waterproof.

If you want to be able to use your coasters outdoors or in areas where they might get wet, resin is the way to go. Resin creates a hard, waterproof surface that will stand up to anything.

To apply a clear sealer, simply brush it on evenly over the surface of the coaster.

Make sure to let it dry completely before using or putting away. For resin, mix equal parts resin and hardener according to the package directions. Then pour it into silicone molds (or whatever mold you’re using) and allow it to cure for 24 hours before removing.

What is the Best Finish for Wood Coasters?

There are a few different types of finishes that can be used on wood coasters. A clear finish will show off the natural grain of the wood and can be applied with a brush, spray, or cloth. If you want to add color to your coasters, you can use a stain or paint.

You can also add a layer of varnish or lacquer for extra protection.

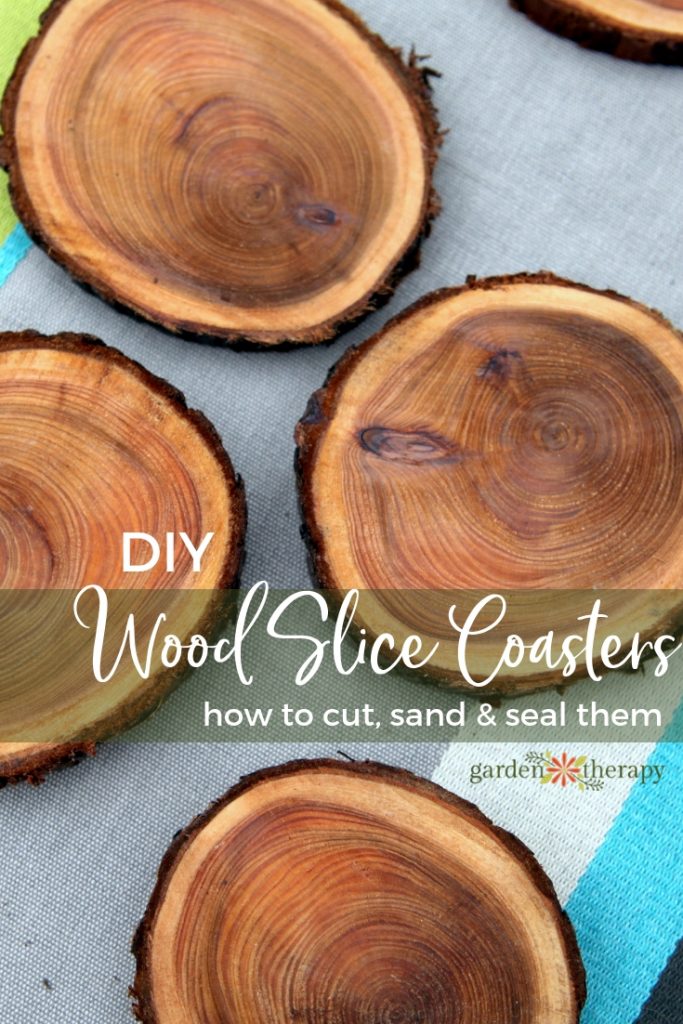

How Do You Seal Wood Slice Coasters?

There are a few different ways that you can seal wood slice coasters. One way is to use a clear polyurethane sealer. This will protect the coaster from water damage and staining.

You can also use beeswax to seal the coaster. This will give it a nice shine and make it more durable. If you want to avoid using any chemicals, you can rub olive oil into the wood.

This will create a barrier against moisture and helps to prevent staining.

How Do You Seal Coasters for Heat?

There are a few ways that you can seal your coasters for heat. You can use Mod Podge, which is a type of glue that is specifically designed for sealing paper products. You can also use clear acrylic sealer or even just clear nail polish.

To seal your coasters with Mod Podge, simply brush a layer of it onto the top and bottom of each coaster. Allow it to dry completely, then repeat the process until you have four or five coats of Mod Podge on each coaster. This will create a waterproof barrier that will protect your coasters from heat damage.

If you want to use clear acrylic sealer, simply spray each coaster with a thin layer and allow it to dry completely before using them. You can also brush on a layer of clear nail polish, although this may take longer to dry than the other options. Whichever method you choose, make sure that your coasters are completely sealed before using them to avoid any damage.

How to make wood coasters (the right AND the wrong way)

Heat Resistant Varnish for Wooden Coasters

Are you looking for a varnish that can withstand high temperatures? If so, then you need a heat resistant varnish for wooden coasters. This type of varnish is specifically designed to protect wood from heat damage.

Wooden coasters are often used in homes and restaurants as decorative pieces or to absorb condensation from glasses. However, if they’re not properly protected, they can be damaged by heat. Heat resistant varnish will create a barrier between the wood and the heat, preventing the wood from scorching or warping.

When choosing a heat resistant varnish, it’s important to select one that is compatible with the type of wood you’re using. Some varnishes are only suitable for certain types of wood, so be sure to read the labels carefully before making your purchase. Once you’ve chosen the right product, follow the instructions on the label carefully in order to achieve the best results.

Conclusion

If you want to make your own wood coasters, there are a few things you need to do in order to seal them. First, sand the coaster down with fine-grit sandpaper until it’s smooth. Then, apply a thin layer of wood sealer with a foam brush and let it dry for 24 hours.

Once the sealer is dry, you can then apply a layer of polyurethane to protect the coaster from water damage. Let the polyurethane dry for 24 hours before using your coasters.