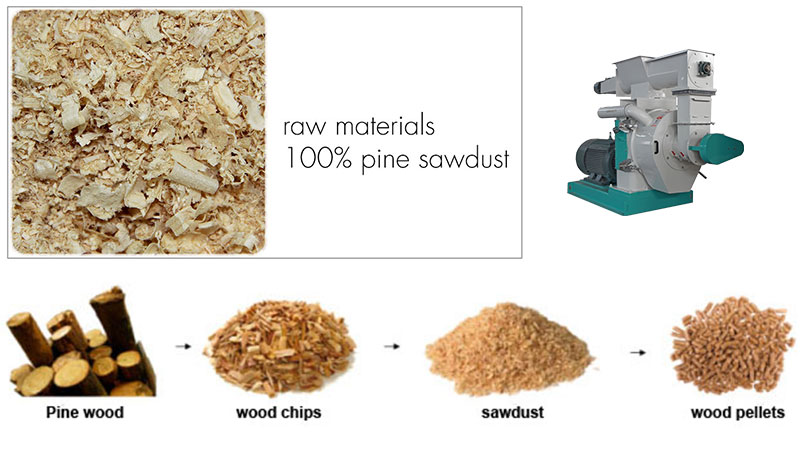

How to Make Wood Pellets from Sawdust

Making wood pellets from sawdust is a great way to recycle this waste material. Sawdust is a by-product of woodworking, and is often considered to be waste. However, there are many uses for sawdust, including making wood pellets.

Wood pellets are a type of biomass fuel, and can be used in pellet stoves or boilers to heat your home. Pellets are made from compressed sawdust, and are a renewable and sustainable source of energy.

Wood pellet machine for homemade pellets production (make pellets)

- Collect sawdust from a woodworking project or purchase it in bulk from a lumberyard or home improvement store

- Spread the sawdust out on a tarp in a well-ventilated area and allow it to dry completely

- Run the dry sawdust through a pellet mill to compress it into pellets

- Store the pellets in an airtight container until you’re ready to use them

How to Make Wood Pellets Without a Mill

If you’re looking to make your own wood pellets, there are a few things you’ll need to know. The first is that you don’t necessarily need a mill to do so – although it does make the process much easier. With that said, let’s take a look at how you can make wood pellets without a mill.

The first thing you’ll need is some sort of grinder. This could be a hand-held grinder, an angle grinder, or even a drill with a grinding attachment. You’ll use this to grind up the wood into small pieces – the smaller, the better.

Once you have your wood ground up, the next step is to add it to a large container along with some water and mix it well. The ratio of water to wood will depend on the type of wood you’re using – softer woods will require more water than harder woods.

Once everything is mixed together, it’s time to start heating things up.

You’ll need to bring the mixture up to around 165 degrees Fahrenheit in order for the pelletizing process to work properly. This can be done in a number of ways, such as using a stovetop or hot plate, or even by setting the container in direct sunlight if it’s warm enough outside.

Once the mixture is heated properly, all that’s left to do is run it through a pellet mill (or similar device) and voila!

You’ve now got yourself some homemade wood pellets!

Credit: www.wood-pellet-mill.com

Can I Make My Own Wood Pellets?

Wood pellets can be made from several types of wood, including hardwoods and softwoods. The most common type of wood used for pellets is sawdust, but other types of wood can also be used, such as shavings, chips, or even small pieces of lumber. Pellets are typically made in a pellet mill, which is a machine that compresses the wood into pellets.

The first step in making pellets is to reduce the size of the wood into small pieces. This can be done with a chipper or hammermill. Once the wood has been reduced to small pieces, it is then fed into the pellet mill.

The pellet mill compressesthe wood under high pressure and heat, which causes the lignin in the wood to bind together and form pellets.

Pellets can be made from both hardwoods and softwoods, but hardwoods are generally more expensive than softwoods. Softwood pellets are typically used for heating purposes while hardwood pellets are often used for animal bedding or barbecuing.

How Much Sawdust Makes a Ton of Pellets?

A ton of pellets typically contains between 150-170 bags of sawdust.

How Do You Make Pellets Step by Step?

If you’re looking to make your own pellets, there are a few things you’ll need to do first. Here is a step-by-step guide on how to make pellets:

1. Gather Your Materials

First, you’ll need to gather all of the materials you’ll need in order to make the pellets. This includes things like a pellet mill, wood chips or sawdust, and a way to bind the pellet together (such as corn gluten meal).

2. Prepare the Wood Chips or Sawdust

Next, you’ll need to prepare the wood chips or sawdust that you’ll be using. This means making sure they are the right size and consistency for your pellet mill. If they are too large, they won’t fit into the mill properly; if they are too small, they won’t create enough friction to bind together and form pellets.

To achieve the right consistency, many people use a hammermill or chipper/shredder.

3. Add Binder and Mix Together Thoroughly Once your wood chips or sawdust is prepared, it’s time to add in the binding agent. The most common binding agent used in pellet making is corn gluten meal – which can be added at a rate of 1-2% by weight.

Once the corn gluten meal is added, mix everything together thoroughly so that it is evenly distributed throughout all of the material. 4 Pelleting Process Now it’s time for the fun part -actually making pellets! This is done using a pellet mill (also sometimes called a “pellet press”).

A pellet mill works by compressing material under high pressure – typically between two rollers – until it forms small pellets that hold together when released from the machine. 5 Cooling and Packaging The final step in making pellets is cooling and packaging them up for storage or sale . First , let them cool completely after coming out of the pellet mill .

Then , store them in an airtight container away from moisture . And that’s it ! You’ve now made your very own pellets !

How are Hardwood Pellets Made?

Hardwood pellets are made from hardwood sawdust that is first ground into a fine powder. The powder is then mixed with water and pressed into pellets. The pellets are then dried and finally cooled before being packaged for sale.

Conclusion

Making wood pellets from sawdust is a great way to recycle this waste product. The pellets can be used for fuel, bedding material for animals, or even as a garden mulch. The process is relatively simple and only requires a few supplies.

With a little effort, you can make your own wood pellets right at home.