What is End Grain Wood

End grain wood is a type of wood that is cut across the grain. This results in a more textured and durable surface. Because of this, end grain wood is often used for high-use items such as cutting boards and countertops.

It can also be used for decorative purposes, such as inlays and mosaics.

End grain wood is a type of wood that has been cut so that the grains run perpendicular to the surface. This makes it very strong and durable, as well as giving it a unique appearance. It is often used for cutting boards, countertops, and other high-use surfaces.

Credit: atilaminates.com

How Can You Tell If Wood is End Grain?

End grain wood is recognizable by its distinct appearance. The fibers of the wood run vertically, rather than horizontally like with other types of wood. This vertical orientation makes end grain wood more durable and better able to withstand wear and tear.

Because of this, end grain wood is often used for high-traffic areas or for furniture that will see a lot of use.

End grain wood can be difficult to work with because the fibers are so strong. However, it is also prized for its beauty and unique look.

If you’re considering using end grain wood for a project, be sure to consult with a professional beforehand to ensure that it’s the right material for your needs.

Which is Better Edge Grain Or End Grain?

End grain and edge grain are both types of wood grain, but they have different properties that make them better for different applications. End grain is the term used to describe the wood grain that runs perpendicular to the tree’s growth rings. This type of grain is more resistant to splitting and chipping, making it ideal for cutting boards and other objects that will see a lot of wear and tear.

Edge grain, on the other hand, refers to the wood grain that runs along the tree’s growth rings. This type of grain is less resistant to splitting and chipping, but it is more flexible, making it ideal for furniture and other objects that need to be able to withstand a lot of weight without breaking.

Is End Grain Better for Cutting Boards?

End grain cutting boards are often thought to be the best type of cutting board. This is because the end grain of wood is more durable and less likely to dull knives than other types of wood. End grain cutting boards are also less likely to show knife marks than other types of cutting boards.

What Does End Grain Mean?

End grain is a type of wood cut that exposes the growth rings of the tree. This cut is usually done at a 90 degree angle to the trunk of the tree. When looking at the end of a piece of lumber, you can see the growth rings radiating out from the center.

The number of rings per inch indicates how fast the tree grew. So, a board with 8 rings per inch grew faster than one with 12 rings per inch.

The term “end grain” refers to this particular cut of wood.

When boards are cut with their end grain exposed, it makes them more durable and resistant to splitting. End grain also has a beautiful appearance, so it’s often used in furniture and cabinetry.

Cutting Boards Explained: Edge Grain vs End Grain

End Grain Cutting Board

An end grain cutting board is a durable and beautiful addition to any kitchen. Made from the ends of hardwood boards, end grain cutting boards are strong and can withstand years of use. They’re also gentle on knives, which helps to keep them sharper for longer.

End grain cutting boards are ideal for everyday chopping and slicing, as well as for more delicate tasks like mincing herbs or garlic.

End grain cutting boards are made by bonding together the end pieces of hardwood boards. The resulting board is then sanded smooth and finished with a food-safe oil or sealer.

End grain cutting boards are often reversible, so you can use either side for different tasks. They’re also usually thicker than other types of cutting boards, which makes them ideal for heavy-duty chopping.

When cared for properly, end grain cutting boards can last for decades.

To clean your board, simply wash it with warm water and soap after each use. Avoid putting it in the dishwasher, as this can cause cracking and warping over time. If your board starts to look dry or dull, you can revitalize it with a few drops of mineral oil.

Just be sure to wipe off any excess oil before using the board again. With proper care, your end grain cutting board will be a kitchen staple for years to come!

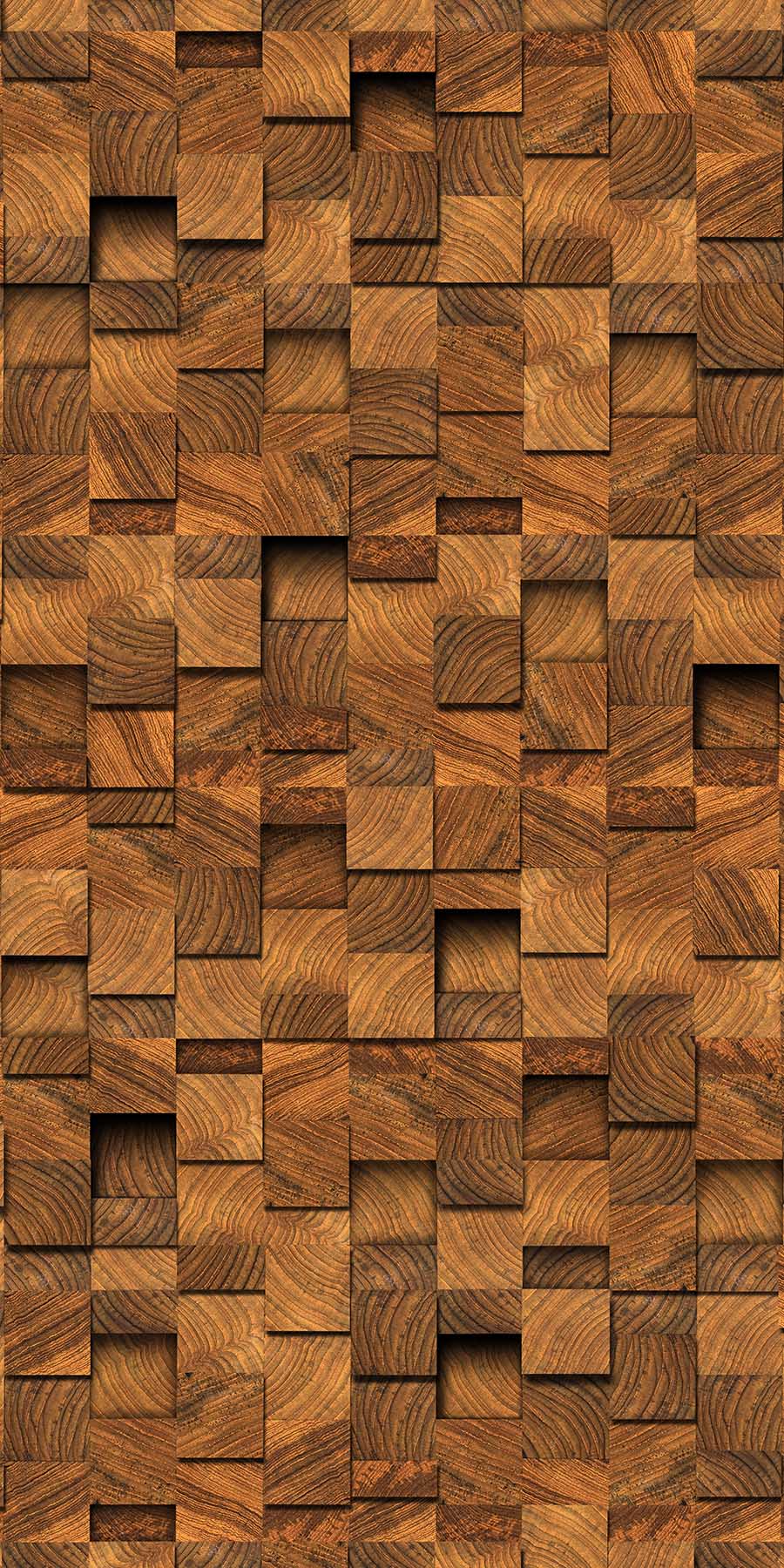

Wood End Grain Texture

Wood end grain texture is a type of wood grain that is characterized by its narrow, parallel lines. It is commonly found in hardwoods such as oak and maple. End grain textures are created when the tree’s growth rings are perpendicular to the board’s face.

When cut this way, each ring appears as a line running across the width of the board. The resulting pattern is unique and can be used to create interesting visual effects in your home.

End grain textures can add interest and character to any room.

They can be used to create contrast against other wood grains or textures in a space. End grain textures can also be stained or finished in different ways to create unique looks. Whether you’re looking for a rustic feel or something more modern, end grain textures are a great way to add personality to your home.

End Grain Vs Edge Grain

There are two main types of wood grain: end grain and edge grain. End grain is the term used for the grains that run perpendicular to the length of the board, while edge grain describes the grains that run along the length of the board. Each type of grain has its own unique characteristics that can impact how your project turns out.

Here’s a closer look at the differences between end grain and edge grain so you can choose the best option for your next project.

End Grain

End grain is often considered to be stronger than edge grain because the fibers are less likely to splinter and tear.

This makes it a good choice for projects that will see a lot of wear and tear, such as cutting boards or countertops. End grain also tends to be more absorbent than edgegrain, so it’s ideal for projects where you’ll be using glue or finish. However, endgrain can be more difficult to work with because the fibers can cause tearing if they’re not cut correctly.

Edge Grain

Edge grain is less likely to warp or cup than endgrain, making it a better choice for projects like tables or shelves where flatness is important. Edgegrain is also easier to work with because the fibers run in one direction, making it simpler to cut and sand evenly.

However, edgegrain isn’t as strong as endgrain so it’s not ideal for projects that will see heavy use. It’s also not as absorbent, so gluing and finishing can be more challenging.

End Grain Wood Cutting Board

An end grain wood cutting board is a cutting board that has been made with the grain of the wood running vertically. This type of cutting board is often thought to be better for knives because it is gentler on the blade. Additionally, end grain boards tend to be more durable and last longer than other types of cutting boards.

If you are in the market for a new cutting board, an end grain wood cutting board may be a good option for you. These boards come in a variety of sizes and styles, so you can find one that fits your needs. End grain boards also make a great addition to any kitchen décor.

Conclusion

End grain wood is a type of wood that is cut so that the grain runs perpendicular to the surface. This makes it more durable and less likely to splinter than other types of wood. End grain wood is often used for cutting boards, butcher blocks, and other items that will see a lot of wear and tear.